At Tekwell Services, we know our variable speed drives. Our service technicians have many years of hands-on, practical experience working on most major brands of VSDs. We understand the value that VSDs bring to your business and how to make sure it runs efficiently to get your work done.

Repairing a variable speed drive (VSD) industrial electric motor involves both the motor itself and its associated drive system (commonly a VFD – variable frequency drive). The repair process addresses issues in either or both components and requires diagnostic precision, specialized tools, and adherence to OEM specifications. Here’s a detailed breakdown of the typical process:

Initial Evaluation and Testing

The repair process begins with a thorough inspection and diagnostic testing:

- Visual Inspection: Check for physical damage, contamination (dust, oil, moisture), loose connections, and signs of overheating.

- Electrical Testing: Includes insulation resistance tests (megohmmeter), surge testing, hipot testing, and winding resistance checks to identify shorts, opens, or ground faults.

- Motor Load Testing: If possible, simulate operational conditions to detect abnormal vibration, current draw, or torque loss.

Disassembly and Cleaning

If issues are confirmed, the motor is disassembled:

- Remove the rotor, stator, end bells, and bearing assemblies.

- Clean all components using a non-conductive solvent and dry thoroughly, especially if contamination was detected.

- Record all part dimensions, configurations, and serial numbers for reference.

Component Inspection

Each part is evaluated for wear or damage:

- Bearings: Checked for noise, pitting, or misalignment. Typically replaced regardless of condition.

- Shaft and Rotor: Inspected for scoring, eccentricity, or imbalance.

- Stator Windings: Examined for insulation failure, heat damage, or contamination.

- Cooling System: Fan blades, heat sinks, and external cooling systems are checked for obstruction or failure.

Repair or Replacement of Components

Necessary repairs or replacements are carried out:

- Rewind stator windings if insulation breakdown or winding failure is detected.

- Replace bearings with new, sealed types suited to VFD use (to mitigate shaft voltage issues).

- Repair or machine the rotor shaft, balance it dynamically.

- Repair or replace cooling fans and terminal blocks.

VFD-Specific Checks

If the VSD is integrated or provided with the motor:

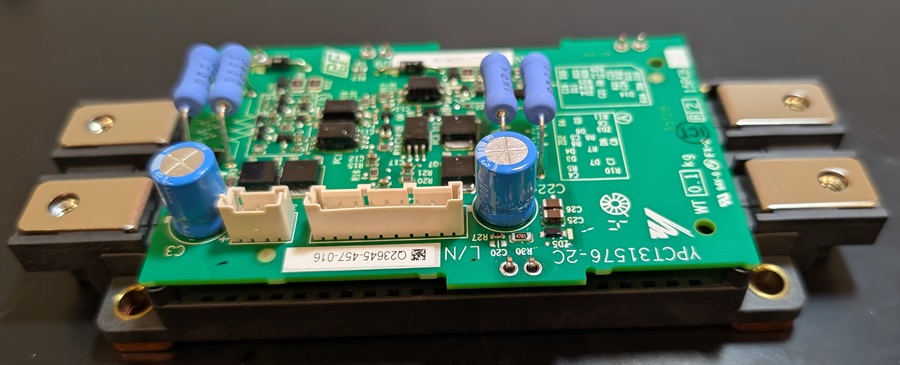

- Inspect power electronics (IGBTs, capacitors, rectifiers) for failure or heat stress.

- Check control boards and firmware for fault logs and error codes.

- Verify output waveform integrity and correct PWM signals.

- Replace any damaged drive components and update firmware if required.

Reassembly and Alignment

Rebuild the motor with precision:

- Install new bearings with proper lubrication.

- Align end bells and ensure the rotor spins freely without contact.

- Ensure all fasteners are torqued to OEM specs.

- Laser align motor shaft if coupling with driven equipment.

Final Testing and Certification

Before returning the motor to service:

- No-load run test: Monitor vibration, temperature, and noise.

- Full-load test (if facility permits): Simulate field conditions to confirm performance under normal operating loads.

- Record all test results and certify the motor for return to service.

Documentation and Return

- A full repair report is created detailing:

- Test results (before and after)

- Components replaced or repaired

- Any recommended changes to application or environment (e.g., surge protection, grounding improvements)

- Maintenance recommendations for extending life post-repair

Proper repair of a variable speed drive industrial motor requires close coordination between our motor technicians and VFD specialists.

Variable Speed Drive Services We Provide

- Input and output power testing

- Diode and IGBT testing

- Control systems

- Connections

- Preventive maintenance

- Installation

- Part Replacement

- Retrofits

Variable Speed Drive Brands We Test and Troubleshoot

At Tekwell Services, we analyze and service most major brands of variable speed drives:

- ABB

- Allen-Bradley

- Control Techniques

- Danfoss

- Fuji

- Siemens

- TECO

- Vacon

- WEG

- Yaskawa

Tekwell Services Variable Speed Drive Troubleshooting

Is it time for variable speed motor service? Call us at 800-829-7454 or complete our by clicking here “Pump and Electric Motor Repair Form” to reach a variable speed motor troubleshooting specialist today.