Early detection of motor and gearbox alignment issues allows problems to be corrected before a component fails. A misaligned electric motor or gearbox can easily damage other connected parts, increasing the time and expense involved in repairs. These failures can create safety hazards and cause unproductive downtime which can be easily prevented.

If left unrepaired, alignment problems could give rise to a “cascade failure” where spiking repair costs approach the cost of new equipment, thus “totaling” your valuable equipment.

Because increased heat is a sign of failure, infrared can detect hot connections in the early stages of degeneration. Some insurance policies require that the infrared cameras must be used specifically for building, mechanical and electrical applications as a measure of preventive maintenance. This is easy to do because infrared thermographic studies can be done non-destructively without taking equipment out-of-service.

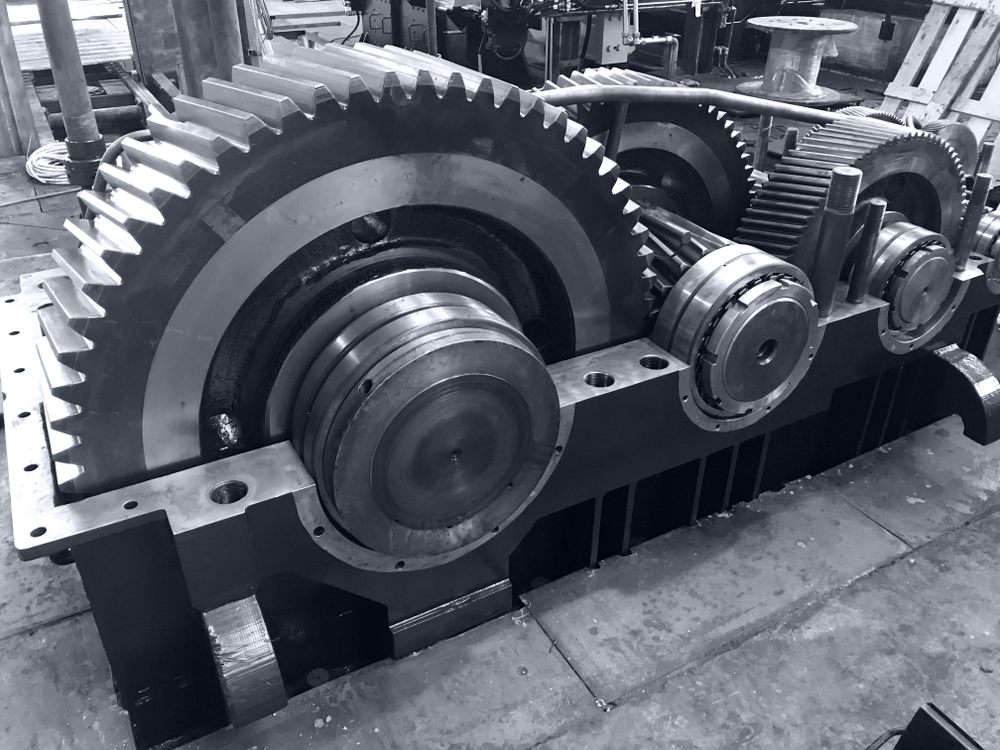

Vibration analysis can find faults in rotating equipment such as gearboxes. When performing a motor and gearbox alignment, using ultrasonic motor testing so that the finest adjustments can be made with confidence. Vibration analysis can detect motor and mount bearing defects, overloads, inadvertently open circuits, loose and deteriorated connections, unbalanced loads, defective equipment, motor and coupling misalignment, and insulation issues.

Other faults that vibration analysis can sense include rolling element bearing faults, and out-of-tolerance resonance conditions. The benefits of finding and fixing these faults are reduced maintenance costs, less downtime, longer equipment life, and lowered repair costs. The trick is to intervene in the early stages of degeneration.

Preventing such catastrophic damage is the goal of electric motor predictive maintenance. At regularly scheduled intervals, the equipment statistics should be analyzed and documented to help experts to spot potential trouble. The business you select should also require that there is no service interruption during inspection.

Putting systems into place for sensing and correcting problems before they raise your repair costs is Tekwell’s area of expertise.

If you would like motor or gearbox alignments or predictive maintenance, give Tekwell Services a call (toll-free) at 1-888-984-4668 or fill out our quick solution form to talk to a motor and gearbox expert today.