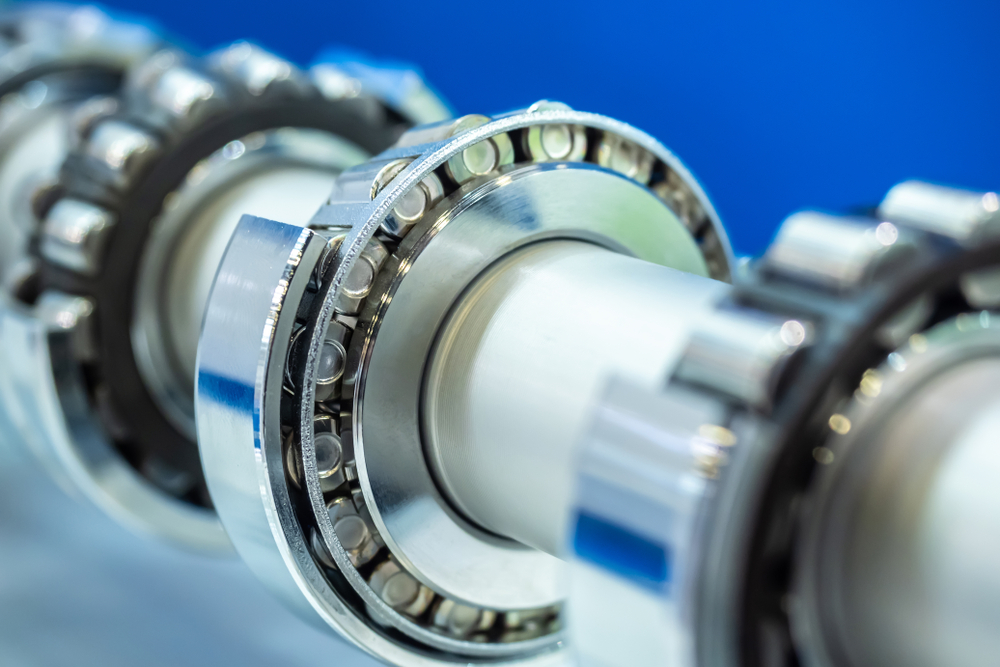

Motor bearings are a critical component of any electric motor, designed to consistently transfer loads from the shaft to the motor and support the rotor. The failure of these bearings typically result in expensive electric motor repairs. Here are some factors you should consider when selecting the best electric motor bearings:

The speed of the shaft directly impacts decisions you need to make about selecting the right kind of electric motor bearing. Some of the factors that need to be considered include:

Load–in respect to the electric motor bearings–is defined as the weights and forces associated with the motor function. The load is also influenced by the amount of power being transmitted, the balance of the motor (out of balance motors may increase the load on the motor), magnetic pull because of unsymmetrical air gaps, and more.

The magnitude and direction of the load will also be a factor in determining which type of bearing you use, especially if you are using the electric motor with gears or belts.

Using the proper lubrication is essential in maintaining a long life for your electric motor bearings. Most of the time this will be lubricant grease, but sometimes oil lubricants are used. Always refer to the manufacturer’s recommendations when using lubricant to ensure the best possible results.

The combination of the proper load and speed is critical when using a lubricant. Electric motor bearings need to operate at a minimum speed while bearing a minimum load in order for the rolling elements within the bearing to generate a lubricant film instead of a skid. Skidding is harmful because it raises the operating temperatures within the motor and degrades the lubricant.

Factors such as the ambient and operating temperatures, moisture, and presence of contaminants such as dust, mud, particles of metal, wood or plastic, all are factors that may impact the type of bearing you select, and if that bearing needs to be shielded or sealed. Moisture in particular is extremely damaging to bearings, so steps always must be taken to mitigate it in humid or condensation prone environments.

We have two locations, one in Knoxville, TN and another in Cartersville, GA (near Atlanta) conveniently located to serve you. Give us a call (toll free) at 1-888-984-4668 or fill out our quick solution form at the bottom of our Contact page, to let us know how we can help.