Bearings are one most important components within an electric motor. The bearing’s role is to reduce rotational friction while transferring the load from the shaft to the motor itself. As a result, the bearing needs to be able to operate at a variety of speeds without frictional loss and be relatively maintenance-free. There are several types of bearings used for electric motor service:

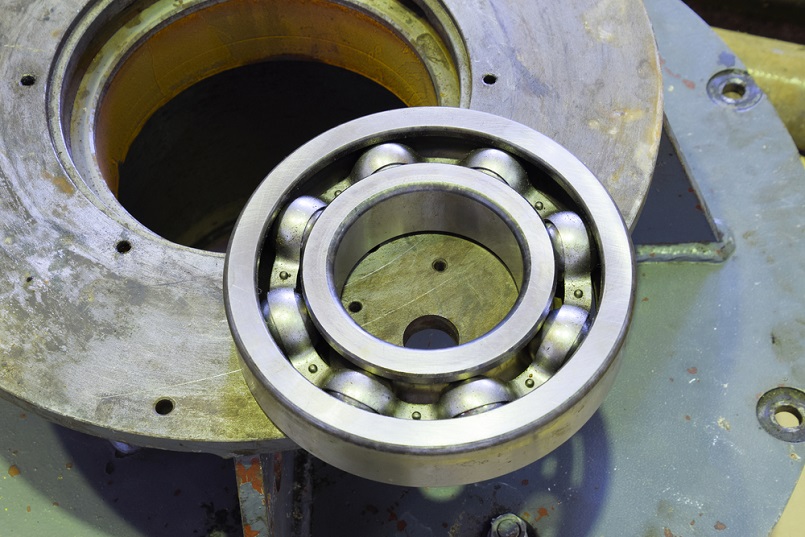

Ball bearings are the most common bearings used in the world. These are typically made from steel or a steel alloy. Some motors use ball bearings because of their versatility to handle both radial and axial loads. These make them perfect for direct coupling (DC coupling) applications.

Most electric motors have mechanical needs demanding some specialized engineering in order to deal with the stresses that they are exposed to. One of these stressors is stray electrical currents. Stray electrical currents damage the bearing, so engineers have needed to develop a special type of bearing to help protect it from these currents. One example of how this was handled was through SKF, who created a hybrid bearing that uses steel rings with silicon nitride rolling elements. These help insulate the bearing from these rogue electrical currents.

As a result, SKF’s hybrid bearings allow electric motors to run reliably at higher speeds, resist contamination, perform better with poor lubrication. This allows these hybrid bearings to have a much longer service life when compared to steel bearings.

The INSOCOAT® bearing from SKF, is a type of hybrid bearing developed for the paper industry to help prevent downtime due to bearing failure. These failures were the result of stray electrical currents damaging the bearings within the pulp boiler flue gas recirculation fan motors. The existing bearings failed about six months before requiring replacement.

The problem was that the lubricant within the bearing would break down rapidly due to the stray electrical currents. One way to prevent this problem is to insulate the housing or shaft, but that was expensive and time-consuming. SKF decided to create a bearing that would manage these rogue currents instead. The INSOCOAT® bearing uses an all-steel bearing that has a ceramic coating applied to it and sealed so that it’s protected against the conductive properties of moisture, making it the perfect bearing for humid environments. This prolongs the life of the lubricant within the bearing, as well as the life of the bearing itself. It also results in better reliability for the user because there is less downtime to replace defective bearings and better performance of the system overall.

Contact Tekwell Services. We are an SKF certified motor rebuilder with locations in Knoxville, TN and near Atlanta, GA, we provide electric motor service all throughout the Southeastern United States. Call us at 1-800-829-7454 or fill out the simple online form on our Contact page or for more information.