Last month we reviewed the initial stages of an electric motor rewinding service:

This month goes over the critical final three stages of the electric motor rewinding service process.

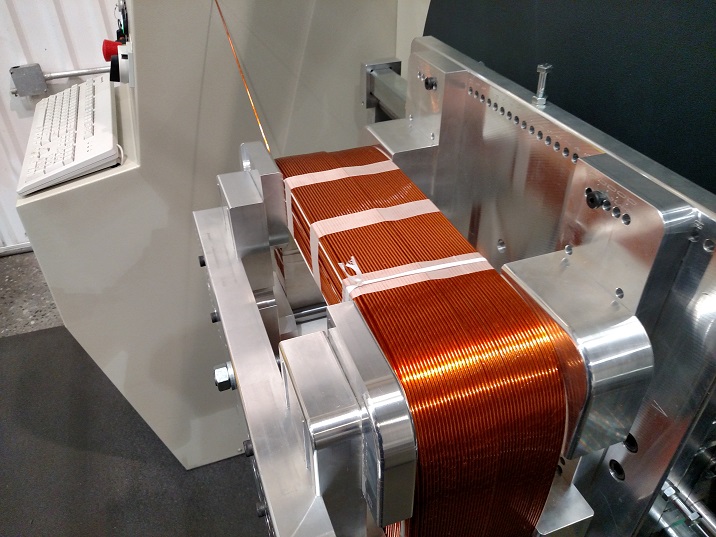

The damaged windings are removed from the core, the cores are tested for core loss, and then the windings are either refurbished or replaced and then rewound back into the motor using as the original configuration of the winding–or a more efficient winding if one is available for your model of motor.

Once the winding is in place, and everything is reconnected, the electric motor service technician completes a series of tests, including surge and hipot testing. Once all of the tests have been completed, the motor is ready for the final stage, reassembly.

This stage is sometimes overlooked or seen not as critical as the other stages in the motor rewinding service process, but if the motor is rebuilt wrong, it won’t be as efficient, so keep the following things in mind while reassembling the motor:

We provide motor rewinding service for most electric motor brands. Contact us for details by completing our online form on our Contact page or call us at 1-800-829-7454.