In the past, if you needed to evaluate the performance of your electric motor you needed to take it offline, where you could test the motor in a motor test bed. The problem with this method of electric motor testing is that it was not an accurate reflection of the motor’s performance in the facility where it operated. A motor test bed tests the electric motor by simulating the best possible conditions.

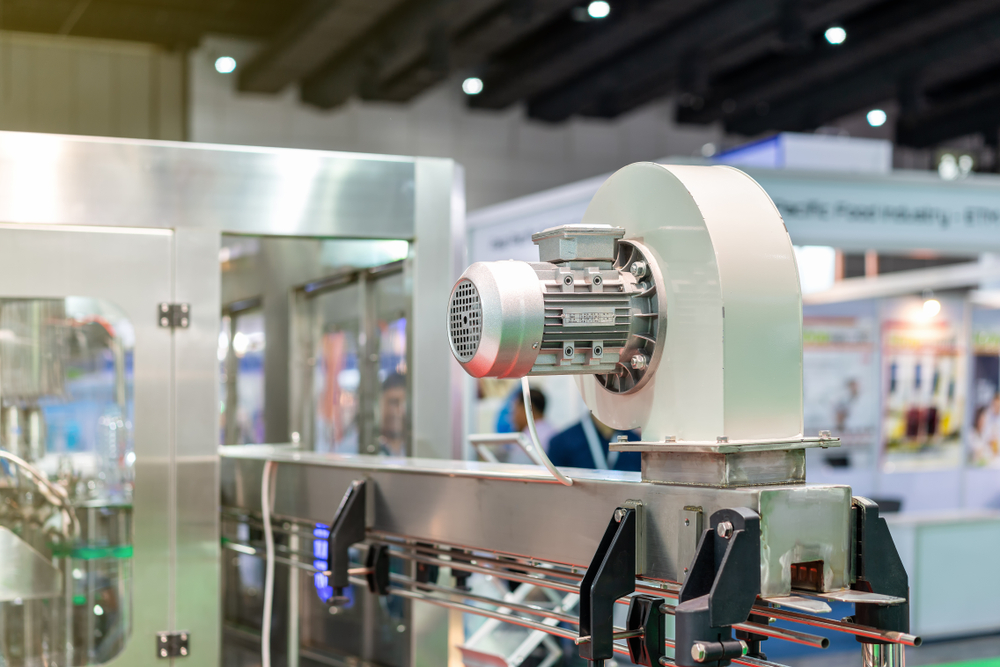

Electric motors are staples in industrial companies all over the world, and some studies have shown that they can consume up to 70% of all energy used by the company. Other studies have suggested that industrial plants consume 46% of all electricity worldwide. 46%! So, it is easy to see why there is a need for an electric motor power quality study. Even one electric motor running with even a small inefficiency can cost the company hundreds, even thousands of dollars each year. These preventable costs may be the difference between the company’s success or failure.

The quality of the electric voltage flowing to an electric motor can impact the efficiency of it. Low voltages, high voltages and even voltage spikes can cause problems such as breaking down the insulation within the motor. Excess voltage can generate more heat and vibration. Here are some of the causes that may impact the efficiency of electric motors:

The biggest benefit of the modern electric motor power quality study is that they can be done while the motor is still in service. They can also be done while the motor is offline, but they work best when the study can see the motor in operation. Most electric motor power quality testers, such as PdMA’s MCEMAX®, are portable and can be brought to the industrial plant where the electric motor is in operation.

Tekwell Services uses MCEMAX®, a complete industrial electric motor testing solution. It can assess the power quality of an electric motor, as well as identify potential issues in the following six fault zones of the electric motor itself: stator, rotor, air gap, power quality, power circuit, and insulation. Schedule an electric motor power quality study from Tekwell by filling out our quick solution form at the bottom of our Contact page, or give us a call (toll free) at 1-888-984-4668 today.