We’ve already covered what a NEMA electric motor is in another blog post. NEMA stands for the National Electrical Manufacturers Association and is an organization that was created as part of the Energy Independence and Security Act of 2007 (EISA). The purpose of this organization is to improve motor efficiency in order to reduce the energy and operating costs for industrial, commercial and institutional buildings and, as a result, reduce the amount of electricity consumed by electric motors and reduce pollution.

One of NEMA’s goals is make it easier for companies to manufacture electrical motors that can easily replace outdated, inefficient motors in a wide variety of environments through the following standard NEMA electrical motor features:

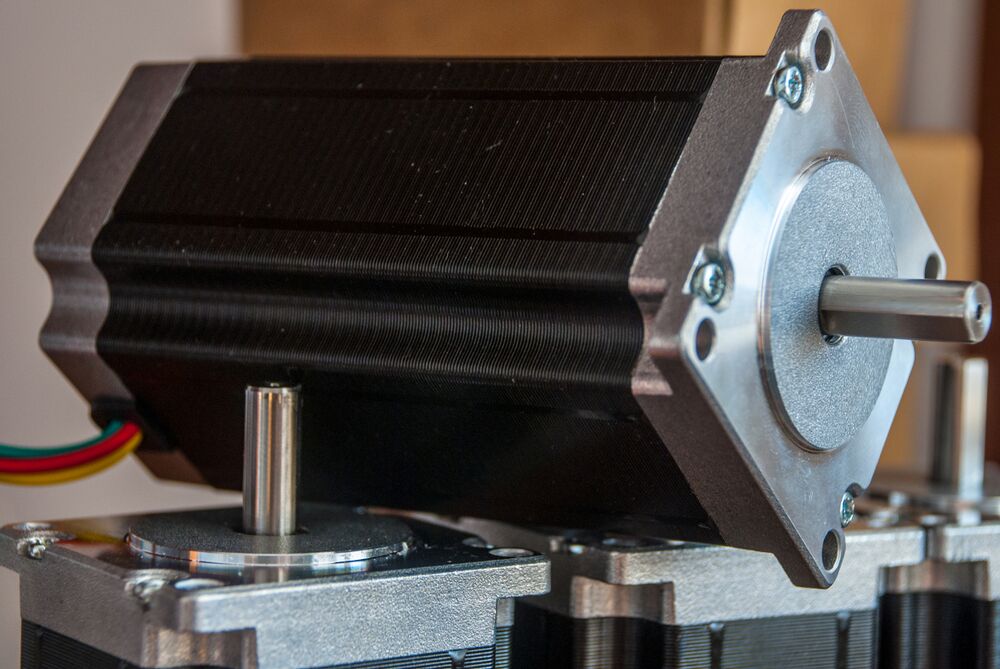

This is critical so that existing non-NEMA motors can be easily replaced without having to rework the engine mount. When you do need to design a new engine mount, the process is easy because the dimensions–including those for the mounting base, the shaft, and even the bolt hole sizes–are well-known and documented. This also makes NEMA electrical motor repair much easier.

There are several different types of enclosures available for NEMA motors which allow them to be used in many different environments. The Open Drip Proof (ODP) enclosure and the Totally Enclosed Fan Cooled (TEFC) enclosure are the most common.

ODP – For motors that need to have open access to air to cool the motor. These enclosures also have internal fans to help the airflow, and prevent liquids such as water and oil, and contaminants such as dirt from seeping into the enclosure.

TEFC – These motors are entirely enclosed and are commonly used for industrial applications where contaminants are a concern such as in paper mills and chemical plants.

NEMA motors have several basic “configurations” designed to meet different needs and demands. Most NEMA motors are standard, general purpose motors used in standard everyday activities.

Severe Duty Motors – These are TEFC motors that are subjected to higher temperatures and more severe environments such as those in the oil/gas production, chemical, mining, industrial foundry, and waste management industries (just to name a few).

IEEE 841 Motors – These motors are designed specifically for the petrochemical and chemical industries where their environment operating temperatures are extreme–anywhere from -25 degrees Celsius (-13 degrees Fahrenheit) to 40 degrees Celsius (104 degrees Fahrenheit) and subject to conditions that may include extreme humidity, chemical exposure and salty environments (such as those near the ocean). These motors must meet the IEEE 841-2009 standards to be used in these environments.

Tekwell provides NEMA electrical motor repair services on both ODP and TEFC-enclosed motors for standard, severe duty, and even IEEE 841 motors. Give us a call at 1-800-829-7454 or complete our online form at the bottom of our Contact page to get started right away.